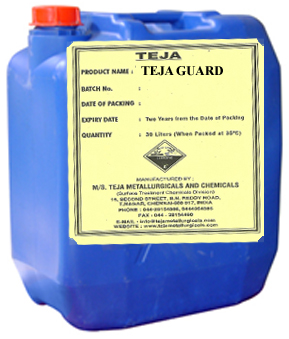

TEJA METALLURGICALS AND CHEMICALS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TEJA METALLURGICALS AND CHEMICALS

Combined Degreasing Derusting And Zinc Phosphating

Product description

Tejaguard is specially developed to remove light oil, grease and mild scale and rust from iron and steel surface at room temperature. It is done by wiping or by dipping the components in the solution. The treated articles can be oiled or painted directly for further rust resistance.

Product Specifications

Colour

water white

Odour

Slightly Pungent

Foaming Tendency

Yes

Reliability

Good

Solubility

Good

pH

Acidic Range

Toxicity

Acidic

Flash Point

Nil

Pollution Hazard

Treatable

Product Operating Data

Concentration

25-33%

Temperature

R.T.

Dip Time

15 – 20 min.

Product Operating Procedure

Immersion Method

Mix one part of Tejaguard with 2 to 3 parts of water in a tank

Dip the components for 15-20 minutes or more, depending upon the amount of rust and oils present.

Tejaguard bath can be heated up to 50-55°C, where uniform derusting and coating operation is required for high rate of production.

Hand Application

Mix one part of Tejaguard with 2 to 3 parts of water

Soak a piece of cotton rag into the solution and apply the solution on the surface of the metal

Rub the cotton rags on the steel surface to loose the oil, grease and rust

Wipe the surface dry

Keep the surface wet throughout by re-using the solution till rust is totally removed.

Product Application Equipment

Tejaguard tank should be fabricated with 4 to 5 mm thick M. S. Plates (preferably SS 316) with continuous convection current hating system.

Safety Measures

Tejaguard is an acidic liquid material, and while handling, proper care should be taken.Protect your eyes, skin, etc. by means of goggles, aprons, gloves etc. If it comes in Contact with skin and eyes, wash thoroughly with a flush of water and get medical advice.

General Information

Corrosion Resistance: Excellent

Paint Adhesion: Good

Gloss Retention: Good.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.